The SWS-300 is a deformation meter for all materials. Its high accuracy allows non-contact

strain control from elasticity range till breaking elongation.

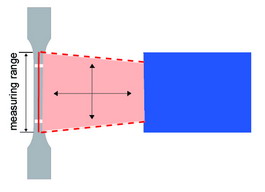

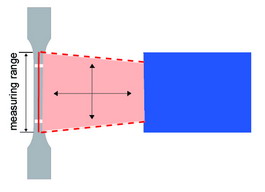

The surface of the specimen is scanned by a laserbeam. A set of stripes applied

to the surface reflects the laser light. The receiver evaluates the reflected light

and changes the signals into digital impulses. The positions of stripes and the

measured lenght are determined from the time process of the signals. A novel deflection

system allows the SWS-300 to measure changes in distance between specimen and scanner.

Advantages

- highest precision up to a big measuring area of 300mm

- accuracy class 1 (referring to DIN EN ISO 9513)

- non-contact measurement with measuring marks

- no influence of specimen by extensometer

- easy integration in testing machine software

- measurement of pressure tests and bending tests

- measurement from smallest to big strains

- determination of E-module without additional receiver or rebuilding

- measurement of changes in distance between specimen and SWS-300

Optional extensions

- the whole experimental run is traceable on screen

- strain-regulated experiments are possible

- local dissolving at mesurement of breaking elongation at welds and assembling components

- force recording with evaluation software for calculation of characteristic values

- applicable to climatic chambers

| Technical Data |

SWS-300 |

| measuring range |

300 mm |

| accuracy class (DIN EN ISO 9513) |

1 |

| resolution |

1 μm |

| lowest measuring lenght |

2 mm |

| working distance (scanner<>speciem) |

250 mm |

| scanning rate |

100 Hz |

| number of stripes |

2 / optional locally resolved |

| Laser safety class |

2 M (no additional protective arrangements nessesary) |

| dimensions/weight |

310 mm x 240 mm x 250 mm / 8 kg |

|